Self-breaking at zero value, easy to detect: Like other types of toughened glass insulators, it has the characteristic of self-breaking at zero value. When defects or aging inside the insulator cause the insulation performance to deteriorate to a certain extent, the glass will automatically break, making it easy for operation and maintenance personnel to observe and detect on the ground or by helicopter, eliminating the need for on-site inspection of each piece, reducing labor intensity, and saving line maintenance costs.

Keywords:

U210BPZ

Product Details

Structural Features

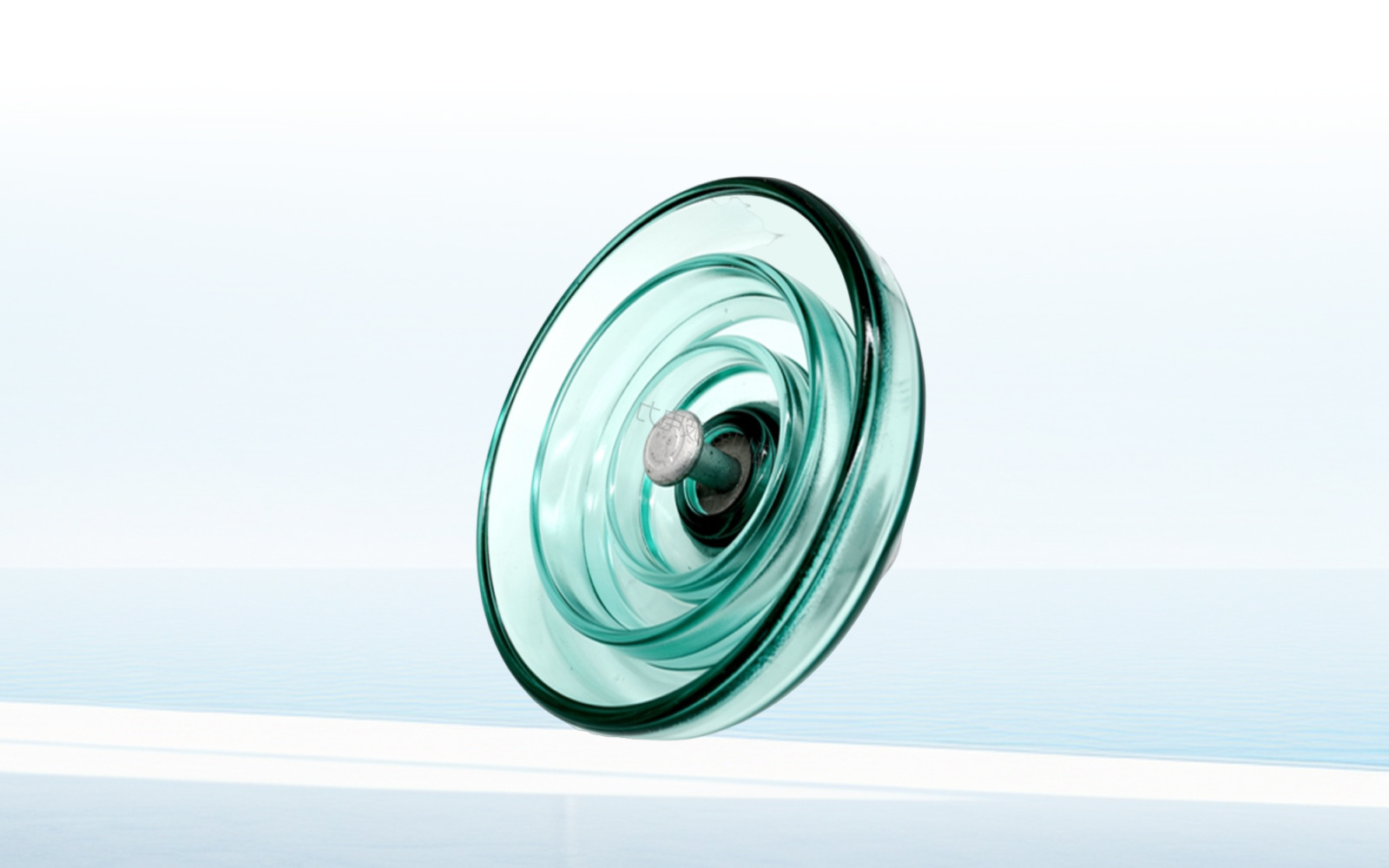

Glass components: Made of high-strength tempered glass, they possess excellent insulation performance and mechanical strength. The umbrella ribs of the glass components usually adopt a design of alternating long and short ribs. This design ensures that the product has a large effective creepage distance, increases the local arc discharge distance, and facilitates the use of natural wind and rain or artificial cleaning of dirt, thereby greatly improving the insulator's anti-fouling flashover level.

Metal accessories: Including iron caps and steel feet, generally made of steel and subjected to anti-corrosion treatment such as hot-dip galvanizing. To prevent electrolytic corrosion, zinc rings and zinc sleeves may be installed on the iron caps and steel feet respectively. The iron cap, glass components, and steel feet are bonded together with cement adhesive to form a stable structure.

Performance Requirements

1. High anti-fouling insulation level: Due to the unidirectional flow of direct current, a "dust collection effect" is produced, causing a sharp increase in the amount of dirt on the insulator surface. Therefore, it needs to have a higher anti-fouling insulation level than AC anti-fouling insulators to ensure that partial discharge can be effectively suppressed in a dirty environment, preventing flashover accidents.

2. Good arc resistance and electrolytic corrosion resistance: Under a DC electric field, local arcs may develop continuously, and the ion migration movement produced by the unidirectional DC current easily causes a large amount of charge to accumulate at the electrodes, accelerating insulator aging. Therefore, DC disc-type suspension toughened glass insulators need to have excellent arc resistance and electrolytic corrosion resistance to ensure long-term stable operation.

3. Higher volume resistivity: Adjusting the proportion of components in the glass formula, such as K₂O and Na₂O, improves the volume resistivity of the product, which helps reduce ion migration, reduce the risk of electrolytic corrosion, and improve the electrical performance of the insulator.

Product Advantages

Self-breaking at zero value, easy to detect: Like other types of toughened glass insulators, it has the characteristic of self-breaking at zero value. When defects or aging occur inside the insulator, causing the insulation performance to drop to a certain level, the glass components will automatically break, making it easy for operation and maintenance personnel to observe and detect on the ground or from a helicopter, eliminating the need for pole-climbing inspection, reducing labor intensity, and saving line maintenance costs.

High mechanical strength: Using high-strength tempered glass and high-quality metal accessories, it has high mechanical strength and can withstand the mechanical tensile force and various stress effects in DC transmission lines, ensuring the safe and stable operation of the lines.

Application Scenarios

Mainly used in high-voltage, ultra-high-voltage, and extra-high-voltage DC transmission lines as key components for insulation and suspension of conductors, ensuring the safe and reliable operation of DC transmission lines under various environmental conditions, especially suitable for areas with severe fouling environments, such as industrial pollution areas and coastal areas.

Main Technical Parameters of DC Disc-type Suspension Toughened Glass Insulators

| Structural Type | Product Model | Mechanical Destruction Load (kN) | Maximum Nominal Diameter D (mm) | Nominal Structural Height P (mm) | Minimum Nominal Creepage Distance (mm) | Standard Connection Mark | Unit Weight (kg) |

| DC Type | U160BLPZ | 320 | 170 | 550 | 320 | 20 | 9.5 |

| U210BPZ | 320 | 170 | 550 | 320 | 20 | 10.2 | |

| U300BPZ1 | 380 | 195 | 635 | 380 | 24 | 14.5 | |

| U400(420)BZ | 360 | 205 | 550 | 360 | 28 | 14.5 | |

| U400(420)BPZ | 380 | 205 | 620 | 380 | 28 | 15.2 | |

| U530(550)BZ | 380 | 240 | 640 | 380 | 32 | 21.5 |

Product Recommendation

Online Message

Leave your contact information and get a free product quotation